A comprehensive strategy for the hygroscopicity of nylon (PA66 modified, PA610, PA612, PA12, PA1010, PA1012, nylon modified, reinforced nylon, flame retardant nylon):

The harm of humidity to plastics:

Considering the humidity factor, when the relative humidity exceeds 80%, the moisture in the air penetrates into the raw material or produces shrinkage water on the surface of the plastic, thus reducing the application performance of the plastic; when the relative humidity in the air is lower than 50 %, the water often contained in the plastic will evaporate into the air, which will also change the performance of the plastic, making some plastics brittle and causing cracks.

The effect of humidity on the performance of plastics is mainly to penetrate into the whole process of digestion and absorption. At this stage, there are two key aspects of scientific research on the impact of humidity on the mechanical properties of plastic structures and structures. Structural in-situ stress and page in-situ stress caused by infiltration of humidity, external diffusion and asymmetrical moisture composition; on the other hand, scientific research on the harm of humidity and temperature to the physical characteristics of plastics, such as compressive strength, relative density, strain rate , service life and other physical performance hazards.

The harm of natural environment humidity to the performance of plastic machinery and equipment is obvious. Generally, plastics that can digest and absorb water are optically active raw materials. Such raw materials can generally produce some types of bonds. Such bonds are most likely covalent bonds. Raw materials such as nylon are such raw materials. On the other hand, moisture has no effect on high-pressure polyethylene or PTFE, and the properties of this plastic are basically plastic in response to changes in the humidity of the natural environment.

The harm of humidity to the performance of nylon mechanical equipment:

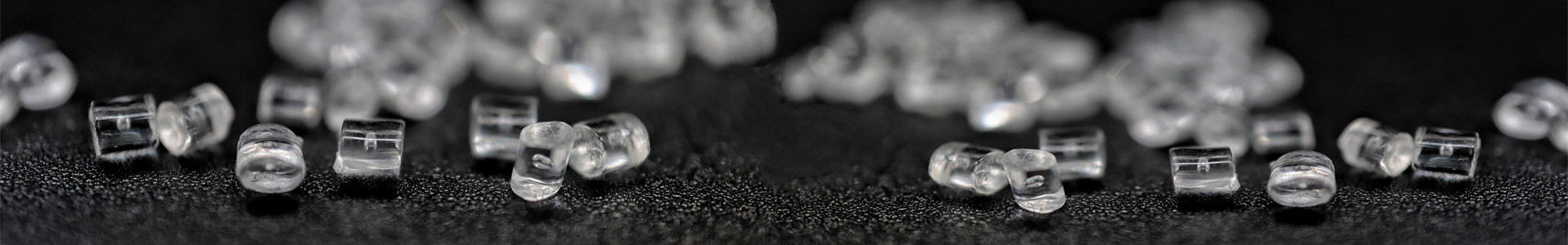

Nylon (PA66 modified, PA610, PA612, PA12, PA1010, PA1012, nylon modified, reinforced nylon, flame retardant nylon) raw material is a kind of high semi-crystalline thermosetting plastic with good physical and mechanical properties , and used in many industrial production. In addition, all nylons are absorbent (moisture-sensitive), and this factor must be highly valued in the selection of raw materials, the design of plastic parts, and the predictive analysis and improvement of mechanical equipment performance.

Hydrolysis can continue to increase the ductility of nylon, and in turn, the lack of water will cause the nylon raw material to become brittle. A study found that the hydrolysis reaction will expand the surface defects and harm the pages of chemical fibers and substrates. He emphasized that the expansion of surface defects and the decline of chemical fibers-substrate pages result in reduced impact performance. High temperature accelerates the hydrolysis of nylon and has long been used in scientific research on accelerated aging tests. In addition, after nylon absorbs moisture, temperature is not the only factor that increases the embrittlement speed, but the increase in temperature will increase this speed.